EconCore

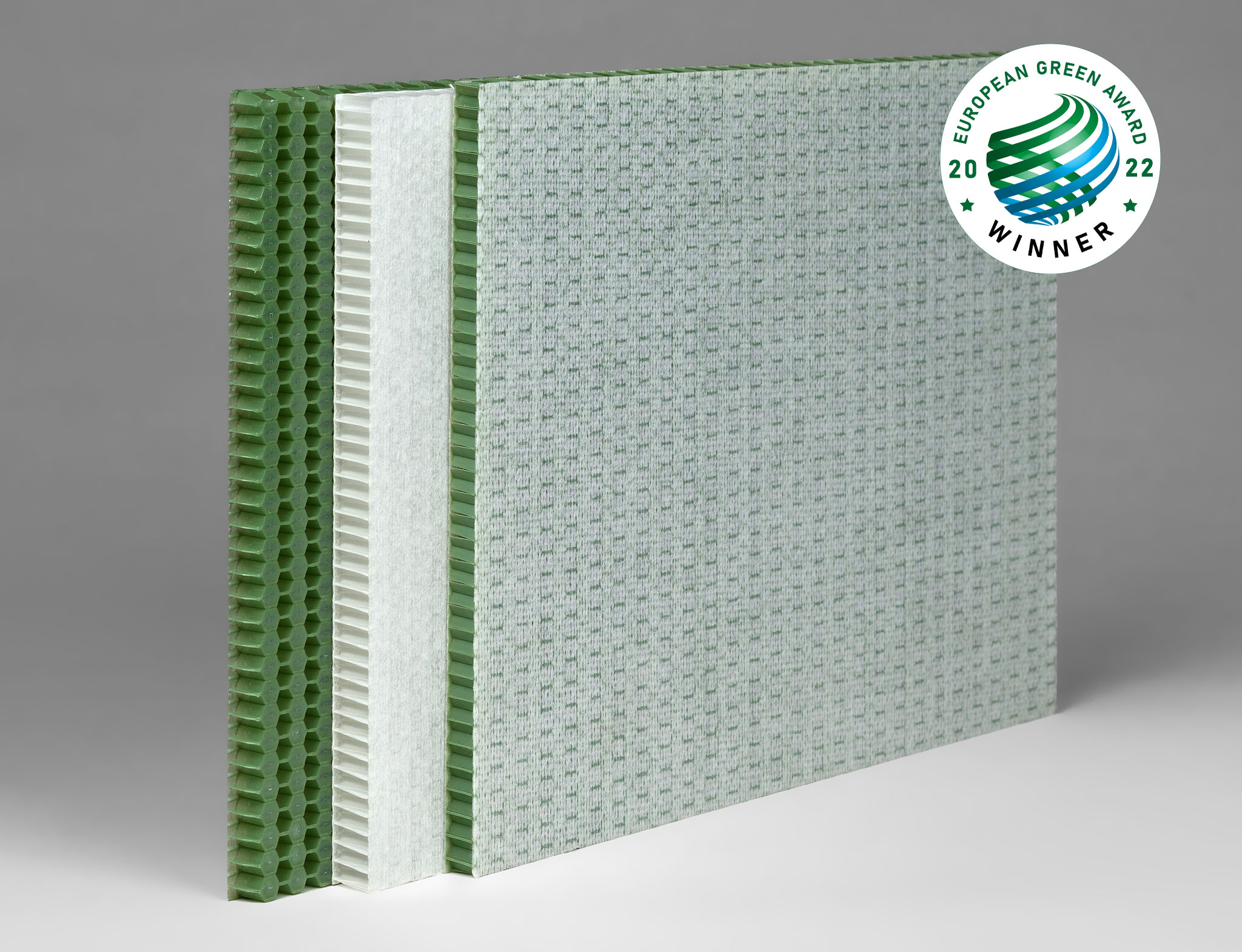

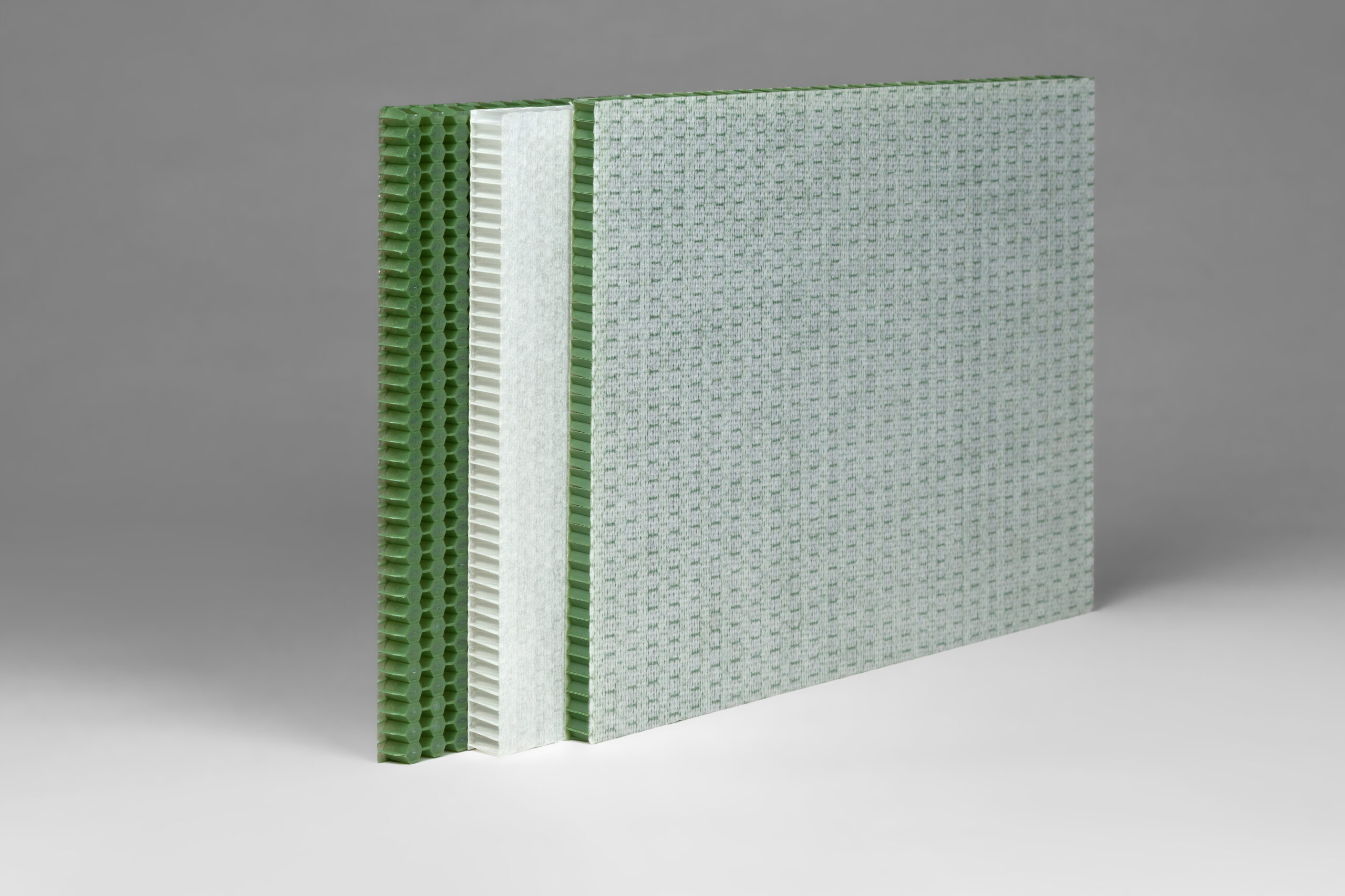

RPET Honeycomb Core Technology

Technology for the cost effective and continuous production of honeycomb cores and sandwich panels based on up to 100% recycled post-consumer waste including PET bottles and other waste.

Gallery

General Description

EconCore has developed a continuous manufacturing process that can produce thermoformable, high performance panels with a thermoplastic core made out of recycled PET, in a cost-effective way. With RPET honeycomb core technology, EconCore is trying the solve the global agglomerated waste problem coming from industries and consumers. This recycling of plastic waste is an important step forward in the pursuit of sustainability, as waste can be converted into performance-to-weight-optimized honeycomb structures.

Beyond RPET from bottles, the technology can also use more RPET waste streams, including consumer and industrial, that are otherwise difficult to find recycling applications. With the RPET honeycomb core, EconCore sees opportunities in many applications such as the automotive market where weight reduction becomes crucial to reduce CO2 emissions. Also, other markets, including industrial packaging and transportation, have applications where this material can be an excellent fit.

Sustainability Impact

Significant weight saving: 60-70% compared to monolithic panels based on PET and PP and other thermoplastic materials.

RPET honeycomb core is an ultra-low density product and the weight reduction translates into minimal use of raw material, delivering performance while saving resources.

The use of RPET honeycomb cores gives a sustainable solution with a good Life Cycle Assessment and low carbon footprint which fits the world-wide sustainability strategy.

Major cost reduction, e.g. panel comparison 50% savings on raw materials compared to virgin PET. 20% Cheaper than mainstream alternative such as foam or virgin PET.

– 100 % recyclable.

– Made of up to 100% recycled material.

– Up to – 79% global warming potential reduction.

Head of Project

Bianka Nagy