Christoph Konheisner | Young Green Change Maker

Project: MySol 3.5k – 2nd Life Energy Storage

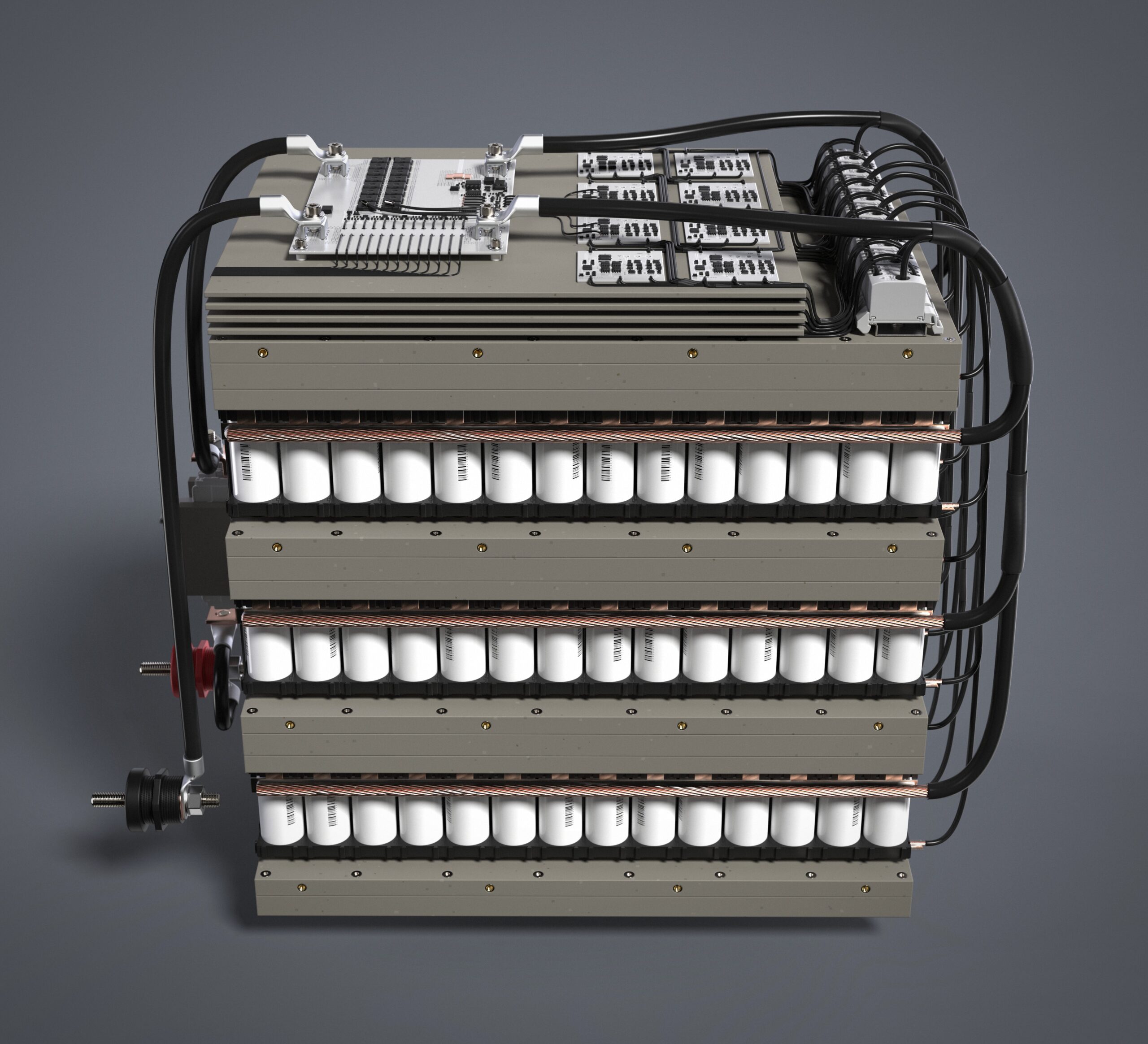

MySol 3.5k is a modular backup battery designed for manufacturing in Africa, constructed from repurposed lithium cells, old printed circuit boards, and plastic waste.

Gallery

General Description

„The project was my master’s thesis and was done in cooperation with ENGIE Energy Access.“ Christoph Konheisner

MySol 3.5k is a modular backup battery tailored for Africa’s energy needs. Designed for manufacturing in Africa, it utilizes 100% repurposed lithium cells, offering affordability and reducing electronic waste.

Only basic tools for production are needed, and it mainly utilizes easily accessible off-the-shelf components. Resource efficiency is heightened by second-life battery-management systems (BMSs) from older devices, improving sustainability. The compression-based electrical contact ensures easy repairability, extending its lifespan – no need for spot welding or soldering. One of its key features is its modularity, allowing customization with different battery modules in terms of size and quantity. The enclosure grows with the battery size and is extruded from recycled ABS plastic sourced from old devices, further underlining the commitment to a greener future.

Sustainability Impact

A significant innovation is the repurposing of old circuit boards, namely BMSs. Often, PCBs are simply recycled after their initial use because they were designed for a specific purpose. In the case of MySol 3.5k, numerous small end-of-life BMSs were combined with the assistance of a small helper PCB to create one large BMS capable of powering the entire battery pack. The result is significantly reduced electronic waste and lower costs.

The entire battery pack utilizes 100% repurposed lithium cells and is constructed from recycled ABS plastic sourced from end-of-life devices. This means that most parts can be procured locally.

MySol 3.5k is highly repairable and built to last. It can be disassembled down to each individual cell due to its compression-based electrical contact. This feature allows for the exchange of broken lithium cells in the future, further enhancing its longevity.

Head of Project

Christoph Konheisner

Additional Credits

- ENGIE Energy Access Supervisor: Raphaël Guiollot

- ENGIE Energy Access Supervisor: Max Schmidt

- University of Turku Supervisor: Tomi Westerlund

Website

https://www.christophkonheisner.com/repurpose